Emissions

Flexibility in Charge Composition

Just as the SuperTurbo’s™ ability to control air flow to the engine allows for greater engine efficiency, this same feature allows for more flexibility for engine tuning to improve emissions. For diesel engines with high pressure EGR, air flow and EGR flow can be varied largely independently. This more precise control over the charge flow composition can help engine manufacturers tune engines for lower emissions.

Lower emissions are also possible during transient engine operation. The quick rise in boost pressure provided by the SuperTurbo reduces over-fueling during transients, improving particulate and smoke emissions. The improvement in air flow during the transient also allows for more EGR flow that would cause excessive amounts of turbo lag in a standard turbocharger, which in turn reduces NOx emissions during transient engine operation.

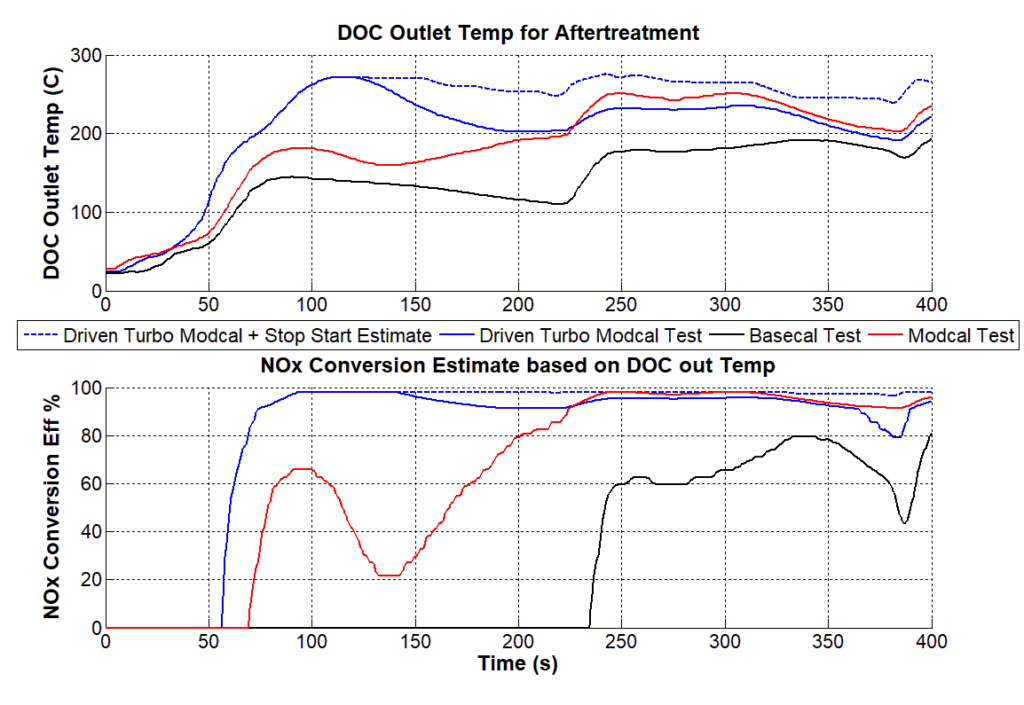

As future government emission regulations tighten for diesel engines, quickly heating up the exhaust aftertreatment during cold start and maintaining the temperature of the aftertreatment will become increasingly important. The SuperTurbo™ allows for an exhaust bypass around the turbine, taking hot exhaust gasses from the engine directly to the aftertreatment, while maintaining the ability to provide boost to the engine through supercharging. Preliminary testing on a heavy duty diesel engine shows the capability to increase main aftertreatment brick temperatures 80-100°C within the first 100 seconds of the cold FTP drivecycle, greatly improving aftertreatment light-off times and conversion efficiency. Even with the exhaust bypass, the engine can still accelerate the vehicle, as the SuperTurbo™ can utilize its supercharging capabilities to provide the engine with the boost required for higher levels of torque.

The flexibility provided to engine manufacturers through the SuperTurbo’s™ ability to control airflow extends beyond the engine performance benefits. The ability to bypass exhaust gasses around the turbine, while still providing boosted airflow to the engine is another tool that can be utilized to quickly increase exhaust aftertreatment temperatures up to operating levels. This enhanced capability for thermal management of the aftertreatment systems enables manufacturers to meet stricter emissions regulations of the future.

Overall, the emissions reductions that are enabled by the SuperTurbo, include:

NOx: Rapid heating of the exhaust aftertreatment allows for high SCR conversion efficiencies extremely early during a cold start. The ability to supercharge through transient operation enables EGR flow during the transients that would otherwise produce unacceptable turbo lag in a conventional turbocharger.

PM: Better air fuel ratios through transient operation improves in cylinder combustion, reducing the amount of smoke and particulates that are produced.

CO2: Improving engine efficiency through improved charge control through transients, as well as turbo-compounding translate directly to savings in CO2 emissions.